Know The Key Safety Tips for Construction Lighting

The seasonal time change creates a higher risk for injuries at work. Employers and staff should be aware of the possible effects on safety caused by the loss of sleep brought on by the daylight savings time change, as well as the shorter days of winter. Studies have shown that the hours of lost sleep can be connected to an increase in job-related injuries in the days following the time change. One way to combat these seasonal hazards is to ensure your construction site has proper lighting.

Construction Lighting: Ins & Outs of Illuminating Your Worksite

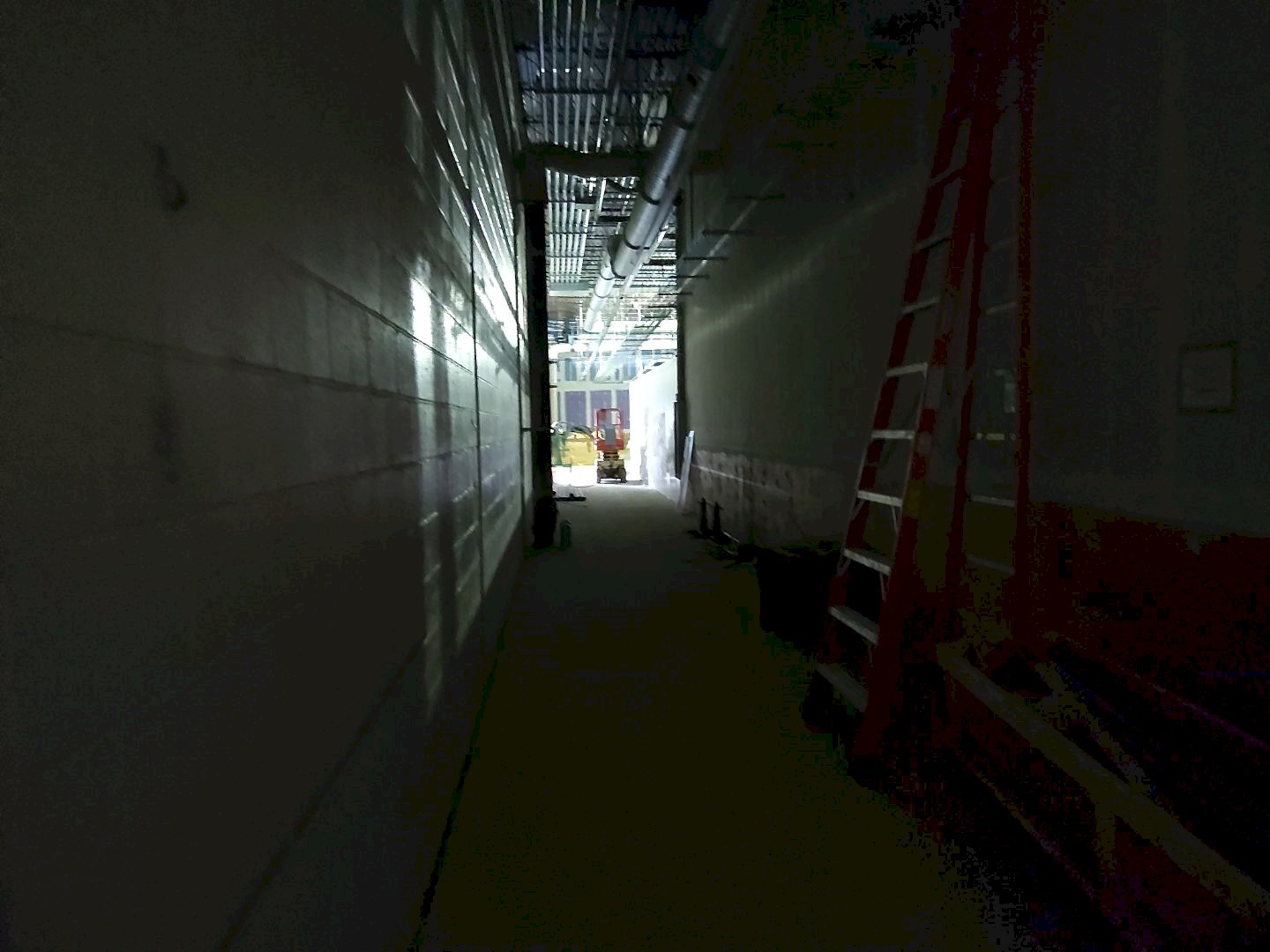

Proper construction lighting, especially during the winter seasonal time change, is essential to worksite safety. It’s just as important for workers as proper equipment and PPE. Proper construction lighting improves twilight and nighttime visibility on the job site and reduces potential work hazards.

Plus, it’s common sense that increasing light levels can maintain productivity levels, as workers can continue project activities. Proper construction lighting also ensures the safety of pedestrians in busy construction zones.

What is the OSHA Standard for Construction Lighting?

The Occupational Safety and Health Administration (OSHA) has outlined a set of specific standards. OSHA standard 29 CFR 1926.56 for construction areas sets minimum requirements, measured in foot-candles, for workers to navigate and avoid hazards. Foot-candles are a unit of measurement that indicates the amount of light falling on a given surface.

OSHA’s standards for lighting are based on the recommendations of the Illuminating Engineering Society of North America (IESNA), a professional organization that develops standards for lighting design and installation.

These standards provide many benefits for employers, including reduced risk of accidents and injuries, increased productivity, and reduced costs associated with lighting repairs and replacements.

These standards are also designed to protect workers from the potential hazards of poor lighting, including eye strain, fatigue, and accidents.

In the OSHA standard 1926.56(a), the minimum foot-candles for each area of operation are outlined. These specific areas include ramps, runways, storage areas, and work sites.

Ensure adequate lighting of at least 5 foot candles in all work areas

Their requirements break down as follows:

• Five foot-candles – General construction area lighting.

• Three foot-candles – Concrete placement, excavation and waste areas, access ways, active storage areas, loading platforms, refueling, and field maintenance.

• Five foot-candles – Indoors: warehouses, corridors, hallways, and exit ways.

• Five foot-candles – Tunnels, shafts, and general underground work areas. Exceptions apply for shaft and tunnel heading, ten foot-candles is the requirement for mucking, drilling and scaling.

• Ten foot-candles – In general shops or construction plants such as screening plants, batch plants, carpenter shops, mechanical and electrical equipment rooms, rigging lofts, active storerooms, mess halls, and indoor toilets and workrooms.

• Thirty foot-candles – first aid stations, infirmaries, and offices.

The Best Construction Lighting Fixtures for the Job

There is no one specific solution for every construction lighting situation, but there are recommended or optimal fixtures depending on the kind of work being conducted.

Here are some recommendations:

String Lights

One of the most common construction lighting fixtures is the classic garland luminary. These are large transparent bulbs that hang symmetrically spaced from a cable and are generally referred to as string lights.

String lights also illuminate hallways and the spaces below them. String lights must comply with OSHA standards and sometimes require heavier electrical cording. Light cords should also be strung from above, not left lying on the floor which could cause a trip and fall hazard.

Temporary string lights must also have a dedicated circuit in case the circuit were to trip and the lights were to go out, leaving workers in the dark.

String light bulbs must also be protected from breakage by using plastic cages that go around the bulb.

OHSA provides several guidelines relating to string lighting safety. OSHA standard 1926.405(a)(2)(ii)(E) requires all lamps for general illumination to be protected from accidental contact or breakage and requires that all metal-case sockets be grounded. And OSHA standard 1926.405(a)(2)(ii)(F) notes that temporary lights shall not be suspended by their electric cords unless cords and lights are designed for this means of suspension.

Lighting must be provided with a dedicated circuit

High Mast Lights

As opposed to temporary fixtures, these are semi-permanent installations. A high mast light, or light pole can be as high as 100 feet tall and supports a luminaire ring, typically composed of four to eight lights covering a large area.

Nite Lights

Nite lights are basically metal halide lamps running at 400 watts covered by a diffusing cloth, creating a softer effect while providing sufficient lighting levels.

Balloon Lights

Balloon lights typically apply to workstations or mount onto equipment or vehicles. The lights have air or helium-inflated covers made of light-diffusing material placed on stands.

LED Lighting

LED lighting has transformed the industry. LEDs have a longer lifespan, are more efficient, and are better for the environment. Some of the benefits of LED lighting is that it saves on energy, materials, and labor for each project, leading to decreased charges for temporary lighting per project. LED floodlights, specifically, can provide optimal visibility for an otherwise dim construction site. Their illumination spans between 50 to 120 degrees of light, creating a large beam that can cover a vast area. And LEDs cover more surface area at an 80 percent lower rate of consumption.

Moving to LED can result in savings of thousands of dollars on electricity since onsite construction lighting often runs nonstop. With the potential to reduce energy consumption by 60 to 90 percent, LEDs are one of the best options for a cost-effective reduction in CO2 emissions.

Proper OSHA Construction Lighting Benefits

Knowing the OSHA standard and all the possible construction lighting options can help you not only provide a safe work environment but can also save you time and money.

Assessing your job site and installing the proper lighting provide many of the following benefits for employers and workers:

• Reduced risk of accidents and injuries

• Increased productivity

• Reduced eye strain and fatigue

• Improved morale

• Reduced costs associated with lighting repairs and replacements

Compliance Consultants, Inc. Can Help You Determine Where to Start

Construction lighting is vitally important in the winter months, but throughout the year proper lighting goes a long way in preventing potential accidents.

Knowing where to start can be confusing. Let Compliance Consultants, Inc. help you assess and determine how to set up your site and which lighting fixture(s) are best for your unique situation.

Get Started Today!

Contact us for more information and we’ll help you develop a plan.

ccicomply.com/contact-us/

Resources:

https://www.osha.gov/laws-regs/regulations/standardnumber/1915/1915.82

https://www.ledvanceus.com/blog/Pages/OSHA-Standard-for-Lighting.aspx