A Job Hazard Analysis Can Mitigate Injuries

A Job Hazard Analysis or Pre-Task Safety Plan Can Mitigate Hazards

What is a Job Hazard Analysis . . . or Pre-Task Safety Plan?

A Job Hazard Analysis (JHA) is one of the main components in safety management. A Job Hazard Analysis or Pre-Task Safety Plan is aimed at preventing unsafe acts, potential injuries, and other harmful situations or activities before they are performed in a particular environment or by a particular type of subcontractor. For example, a concrete contractor will have different safety considerations from an electrical contractor. Each contractor has their own unique safety considerations, equipment, and mitigation procedures.

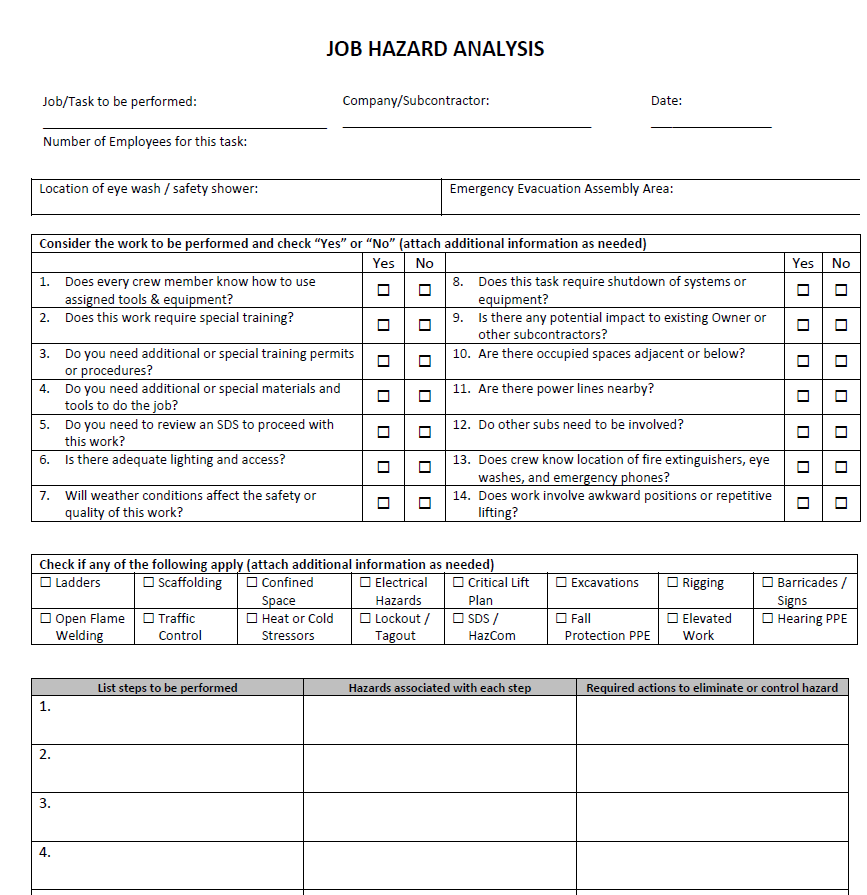

A Job Hazard analysis or Pre-Task Safety Plan is a proactive method of identifying and mitigating hazards before they occur. It breaks down a task into specific steps, the hazards associated with each step, and the safety equipment, processes, or PPE needed to perform them safely.

A Job Hazard Analysis can be initiated by the overall general contractor or a specific subcontractor. It requires that the responsible contractor document exactly how they will prepare, inspect, and mitigate all relevant safety tasks while they are working on site. Most importantly a Job Hazard Analysis is designed to keep workers safe, improve performance and assure a safe outcome of the overall project.

How Do We Prepare and Implement a Pre-Task Plan?

Not all pre-task plans need to be in writing, but it’s certainly a good idea, especially for tasks that have a high hazard level. Depending on the complexity of the task, multiple meetings may be required to address all hazards. Pre-task planning should account for factors like anticipated duration of the project, the number and type of workers needed, equipment needed, actual or potential hazards on the site, the personal protective equipment needed for each worker, availability of rescue personnel, and mitigation steps needed to assure a safe environment. From these planning meetings, your team can then develop the Job Hazard Analysis. The JHA should be reviewed with all relevant workers and signed prior to beginning the task.

Alternatively, for smaller, less complex tasks, a pre-task safety plan may be as simple as a Safety Huddle or Briefing at the beginning of the shift. Review with workers the tasks for the day, what the process should look like, the potential hazards they may encounter, and how they can stay safe. Make sure everyone has the equipment, materials, and PPE needed to work safely.

Pre-Task Planning Tips

- Set expectations and a process to measure engagement with your Pre-Task Plans. Consider simple methods of recording and reporting to know who submits a plan and when and how they are reviewed.

- Ensure that prerequisite documents are reviewed and approved.

- Verify tools, equipment, and training expectations

- Attend site meetings to gain understanding of the site safety measures and be able to coordinate with other site trades.

- Do a “walkabout” of the work area with your team to discuss the tasks outlined for the day and encourage open communication of potential safety hazards.

- Keep it easy: Remove barriers and streamline procedures for supervisors and crew.

- Leverage the expertise of the individual trades for safety input.

- Use your JHA and Pre-Task Checklists to review, reinforce, and guide the daily meeting conversations.

- Stress open communication with the entire team. The more safety minded your team is the more benefit to everyone.

- Be an example for safety. Show engagement at all levels of the organization and encourage participation.

- Work to gain consensus from every member of the project team.

- Revisit the checklist often and work to identify new areas of safety concern.

- Be flexible regarding making changes to safety issues. Strive for continuous improvement.

Continuous Process Improvement

Before the start of work each day or at the end of the day, it’s a good idea to gather feedback from all team members regarding safety issues and improvements, and successes from previous days, and incorporate these ideas into ongoing process improvements. The idea is to continuously identify, mitigate, and make improvements. The goal is to discuss any and all possible hazards, safety issues, and equipment needed to provide and maintain a safe work environment.

The Many Benefits of Pre-Task Safety Planning

The benefits of a pre-task safety plan are many. It’s vital to have a plan in place that covers your business when it comes to safety enhancement and field engagement.

When used effectively, Pre-Task Planning, including a Job Hazard Analysis, drives proactive safety performance and productivity which keeps your teams on schedule and on budget.

Some of the most important benefits include:

- Empowerment: Employees and trades take end-result ownership when they get a say in the plan.

- Quality: Process consistency means fewer mistakes, fewer reworks, higher productivity, and a better quality of work.

- Communication: the General Contractor, Project Manager, and Superintendent gain transparency of who’s on-site, where they are working, and what they are working on. This lessens work stoppages and intermingling trade issues.

- Return on Investment: Reduced direct and indirect incident costs by way of schedule impacts, reworks, medical bills, employee turnover and morale, public image, worker’s compensation, and fines and penalties have a significant impact on the bottom line.

- Innovation: Improvements are made when an employee shares a best practice or new tool.

Be a Planner… Work Smart, Not Hard!

Project work sites are active and ever-changing. Pre-take safety planning is crucial in helping you stay on top of those changes and maintaining a safe working environment. This upfront planning and documentation assures that all subcontractors and trades, with specific safety issues have their needs addressed.

Pre -task safety planning takes commitment and effort but there are many tangible benefits and you have the value of an added “insurance policy” of having documentation of your commitment to safety should OSHA show up at your site. Plus, your investment in safety planning will reduce injuries, reworks, fees, fines, and clear audit trails, so at the end of the day you and your team get home safely.

How Can Compliance Consultants, Inc. Help

Compliance Consultants, Inc. can help you get started with your pre-task safety planning program. We can help you identify areas of concern and guide you toward developing a checklist that addresses your specific needs.

Contact us today to get started!

Resources:

Download a Sample JHA from The Center for Construction Research and Training (CPWR)

https://www.osha.gov/safety-management/hazard-Identification